Designing financially profitable, controlled environment agriculture solutions

Designing financially profitable, controlled environment agriculture solutions

Controlled Environment

Agriculture

The Concept

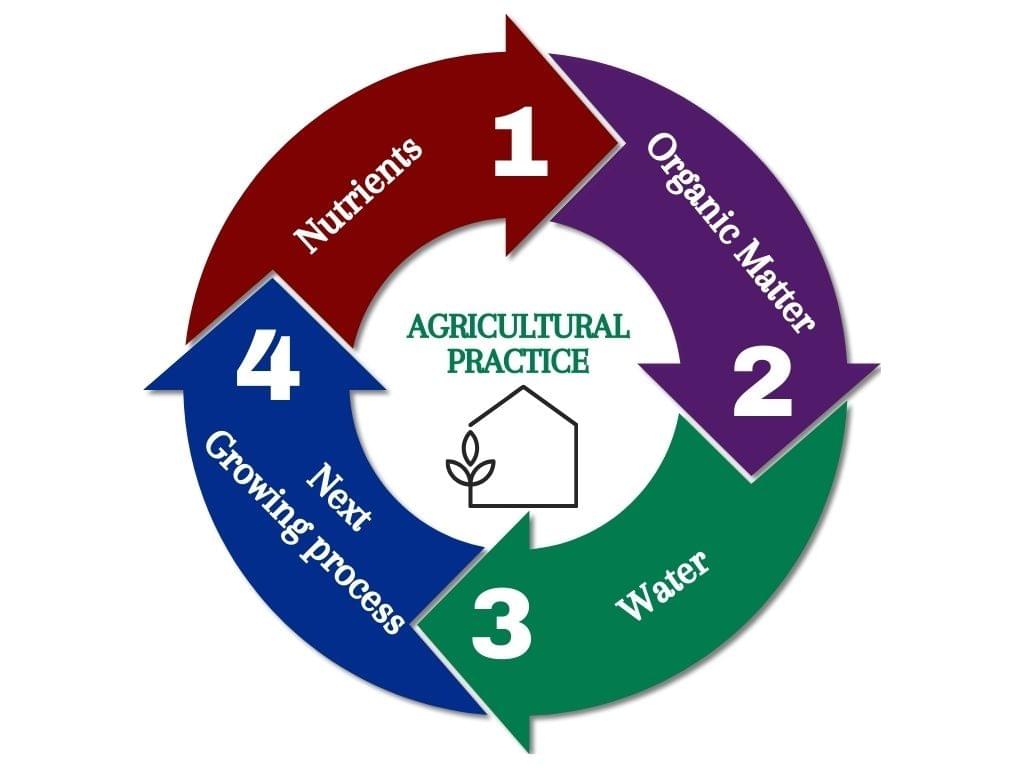

Controlled environment agriculture is farming practice that recycles nutrients, organic matter and water back into the next growing cycle

while concurrently avoiding pollutants. This forms part of an agricultural practice that preserves the nutrient and carbon levels within the soil and or growing foundation and allows farming to be carried out on a predictable and sustainable basis.

The Challenge

To reach sizeable market shares, CEA produce will need to reach cost parity with field-grown organic produce — especially given current marketwith high inflation where consumers are more cost-conscious. (Reference: RolandBerger Analysis of CEA)

The Models

Termian Technology is applicable to three models of CEA growing:

- Traditional greenhouse designs modified to increase yield of a limited range of crops on a seasonal basis

- High tech greenhouses using hydroponic, aeroponic and soil based growing systems to generate both continuous and seasonal crops, often located close to urban areas with requirements environmental compatibility

- Vertical farm designs using hydroponic, aeroponic and aquaponic systems growing continuous crops, often located in an urban area

The Solution

The design solution for Controlled Environment Agriculture begins with the products ready for delivery, and then works backwards. Conceived operations must be considered as a whole entity from financial footing to shipment to market.

- Crop preparation: Was the crop ready for harvest, and what metrics were used to make that determination?

- Nutritional uptake: During growing were the nutritional environmental requirements met and what metrics were utilized

to ensure that? - Growing medium: Prior to planting was the medium optimized to account for outdoor seasonal variations that might impact

indoor environmental management control. - Facility design: Was the design of the facility such that it minimizes redundant operating intervals; that is, from the first input of raw materials to the finished product going to the truck is the flow of human, nutrient and environmental management linear?

- Facility site: Was the facility site selected to optimize operating and marketing challenges?

- Site accessibility: Is the site physically suitable for the project and will the zoning accommodate it?

- Utilities and workforce access: Are public utilities suitable for the projected operation available? Will the site neighborhood support workforce recruitment?

- Supplier arrangements: Is the site conveniently located to raw materials sources including nutrient and packing supplies?

- Transportation access: Will the site accommodate receiving and shipping truck traffic?

- Market proximity: Is the site proximate to a population center sufficiently large to consume the finished products?

- Financial model: Is a financial model in place that takes into account construction development costs, as well as start-up and

initial operating expenses until cash flow income matches operating costs?